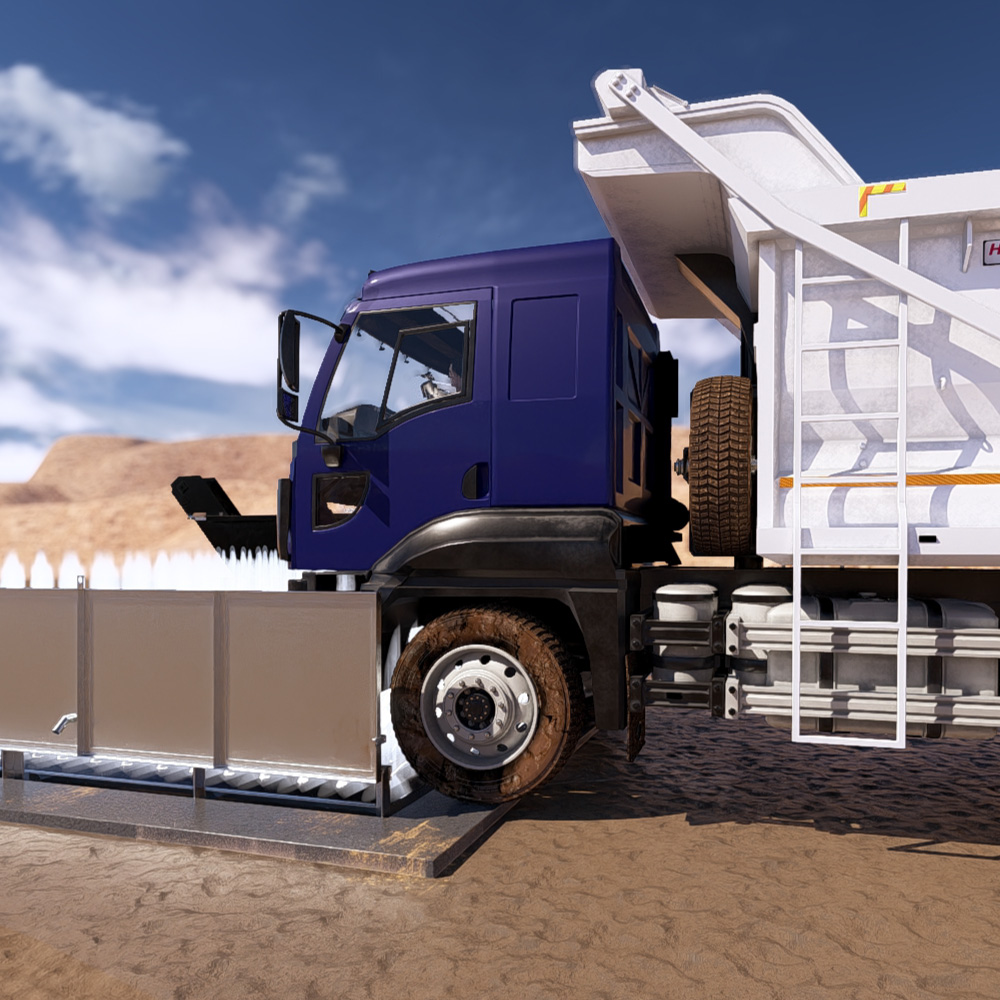

The above-ground system for integrated washing and weighing

The WashWeighBridge® LPxx.32E series is the ideal choice for above-ground applications, combining washing and weighing in a single integrated and modular solution. Designed for complex and ever-changing environments, such as temporary construction sites or logistics hubs, this series delivers high performance with quick and flexible installation, perfectly suited to meet relocation needs or logistical adjustments.

Variants available

LP14.32E

LP18.32E

Up to 60 tons

Fully above-ground

High-capacity closed cycle

16-48 m³ capacity

Automation and monitoring

For construction, logistics, and industry

Advanced features

Technical details

The WashWeighBridge® LPxx.32E system is designed to provide easy and secure access even for large vehicles, thanks to entry ramps that can be constructed either in steel or reinforced concrete (RC). The choice between steel and RC allows the infrastructure to be tailored to the specific needs of the site, whether it is a temporary installation, where quick assembly is critical, or a permanent setup requiring a more robust and stable structure. The ramps facilitate the alignment and transit of heavy vehicles onto the weighing platform, optimizing operational flow and minimizing access and exit times.

The LPxx.32E series integrates an advanced automation system that minimizes the need for manual intervention, enhancing operational efficiency. Remote monitoring via TcConnect and PC Truck enables seamless control and management of the system, providing instant access to operational data and diagnostics. Advanced features, such as automatic license plate recognition and adjustable activation sensors, optimize washing and weighing workflows, reducing wait times and improving vehicle traceability. This advanced automation system is particularly beneficial for high-intensity sites, where operational continuity and precise data are essential for efficient activity management.

Why choose the LPxx.32E series?

The LPxx.32E series represents an integrated solution that optimizes washing and weighing operations, delivering efficiency and sustainability in a single modular system. The key advantages make this series the ideal choice for industrial settings and construction sites.

Operational efficiency

Environmental sustainability

Adaptability and flexibility

Automation and remote control