Innovation that is redefining the engineering for industrial washing and weighing

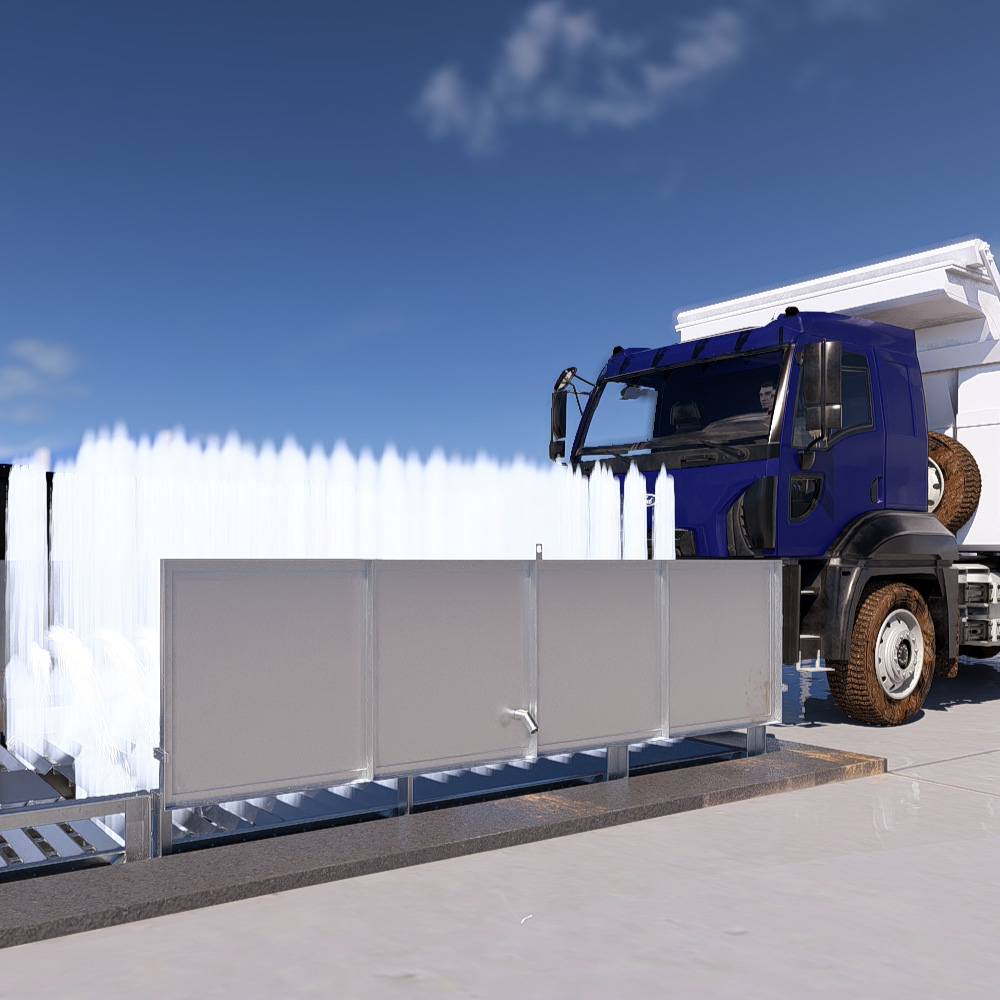

Tecnoter introduces a groundbreaking system that revolutionizes the industry, delivering a sustainable solution that redefines standards of efficiency and reliability.

Integrated and Modular Solution

Exceptional Strength and Durability

Integrated Automation and Sustainability

Advanced Technologies

The WashWeighBridge® system offers complete and advanced automation, eliminating the need for a dedicated operator and optimizing the entire washing and weighing process. With integrated detection sensors and cameras, weight and license plate verification are fully automated, ensuring accuracy and reducing the operational times. Load notes are autonomously generated and archived, enabling seamless and continuous operations. Additionally, TcConnect allows remote management of the entire system, providing real-time monitoring of both structure and performance.

- Full Automation with TcConnect and PC Truck

- Integrated License Plate Detection and Reading

- Operational Traceability and Real-Time Reporting

Innovative Materials and Durable Design

Built to last even in the most demanding operational conditions, the WashWeighBridge® uses carefully selected materials and advanced construction techniques to ensure long operational life, reliability, and durability. The hot-dip galvanized steel and modular structure guarantee operational longevity and adaptability in any environment.

- Hot-Dip Galvanized Steel Structure for Maximum Strength

- Modular Design for Customizable Configurations

- Construction Techniques for High-Stress Environments

Sustainability and Environmental Impact Reduction

The WashWeighBridge® employs a fully closed-loop washing process, drastically reducing environmental impact and operational costs. Water is continuously reused thanks to an advanced clarification system that retains sludge and oils. Waste reduction is optimized through automatic sludge compaction, which reduces weight and disposal costs.

- 100% Closed-Loop Water Recycling

- Sludge Management with 50% Volume Reduction

- Filtration and De-oiling for Clean and Safe Effluents